---------------

The battery-electric drive concept of our ship fleet can be made even more efficient by adding sails, so that more electrical energy is ultimately available for feeding into Europe, i.e. drive losses are reduced and the overall efficiency is improved.

The International Maritime Organization (IMO), which is responsible for standards in shipping, supports new technologies and has announced climate-neutral shipping by 2050.

---------------

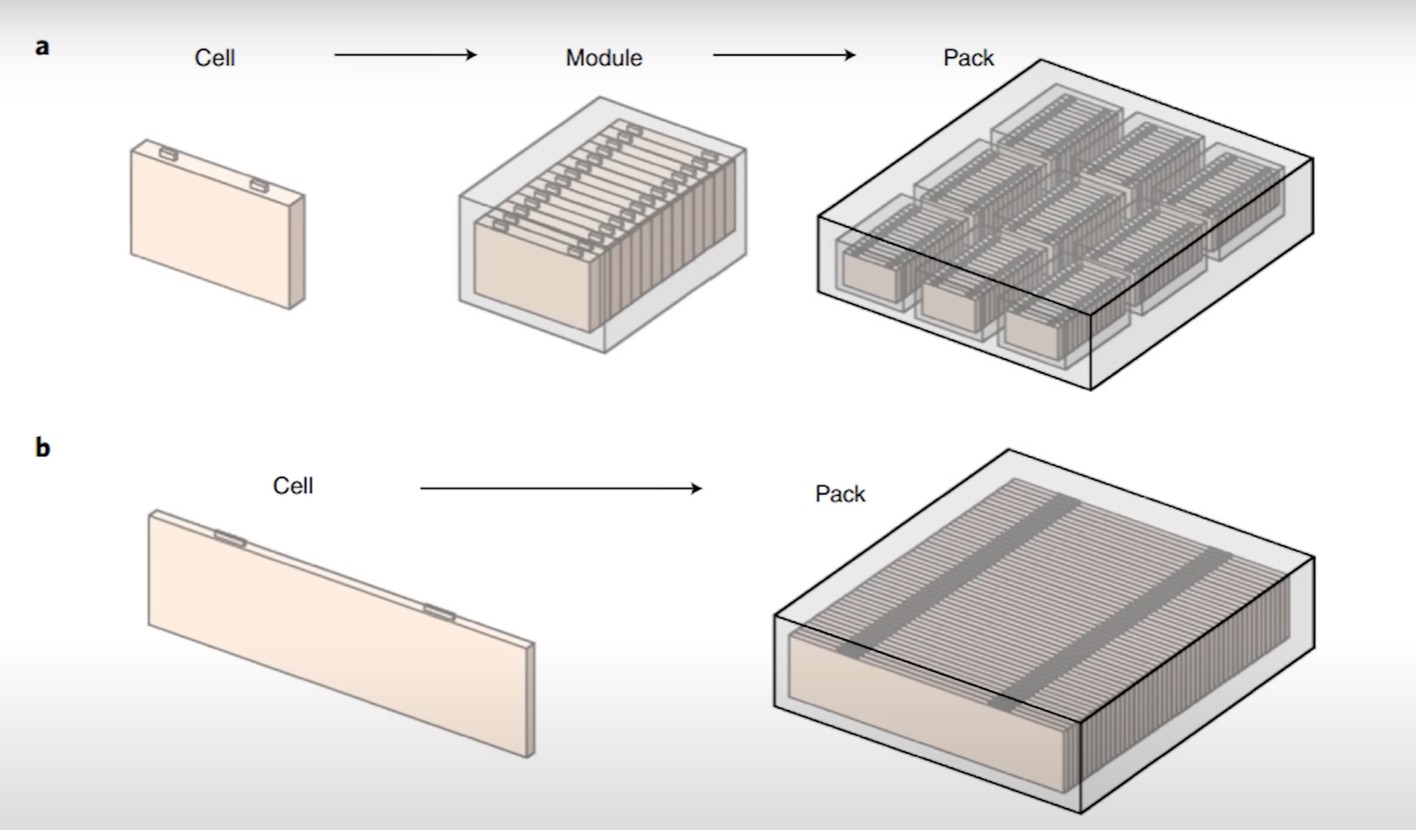

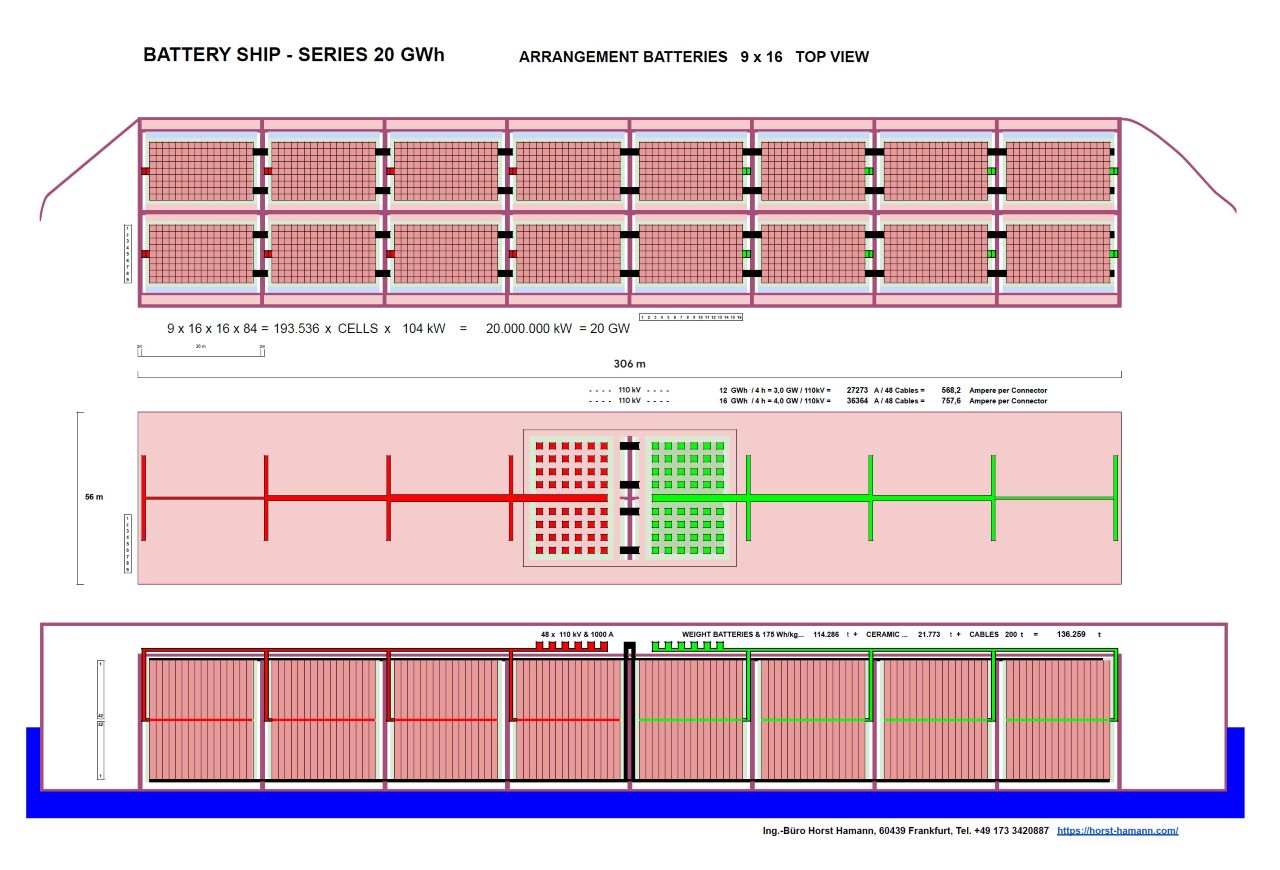

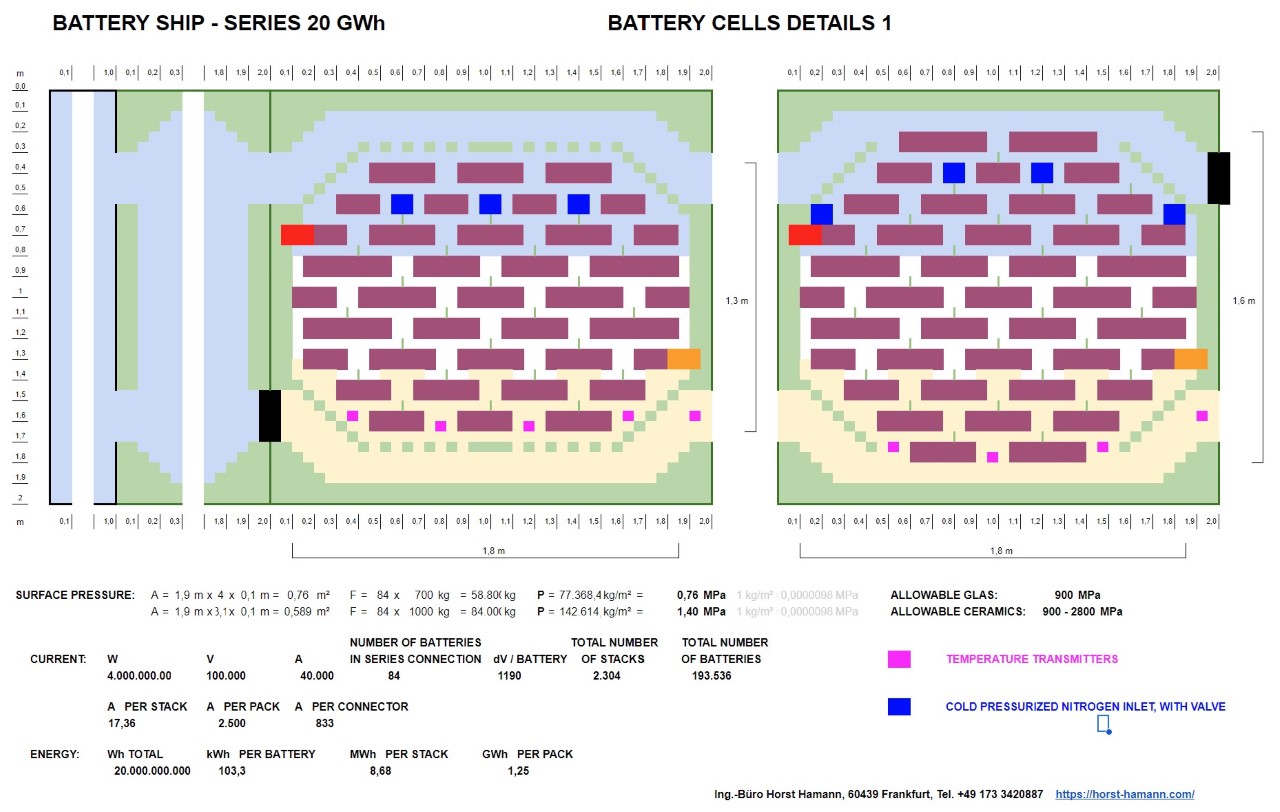

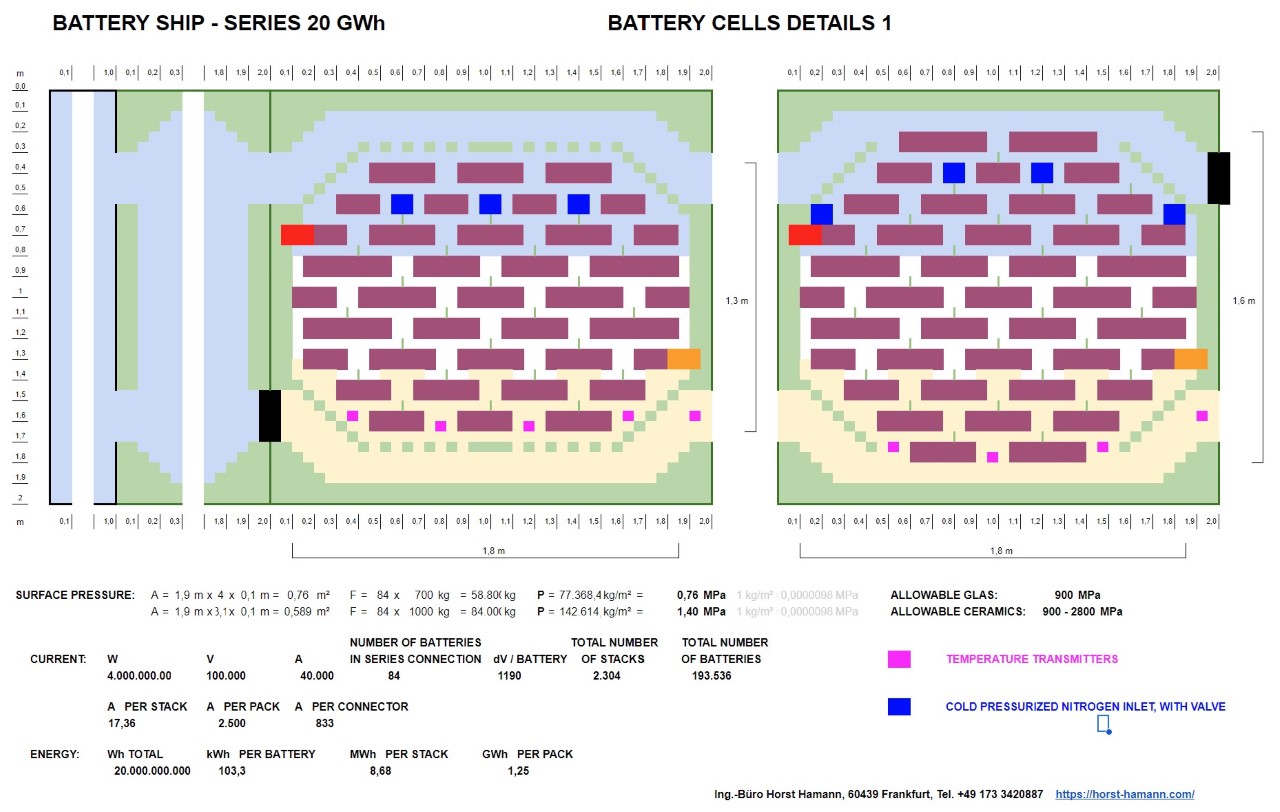

The battery cell housings are of ceramic compond and vertically as well as horizontally connected by form fit.

(design 2020-2021)

Other important components are offshore barges with automatically tracking and gripping, storm-proof connectors for a solid power connection with 48 connectors of 110 kV and 850 A each.

---------------

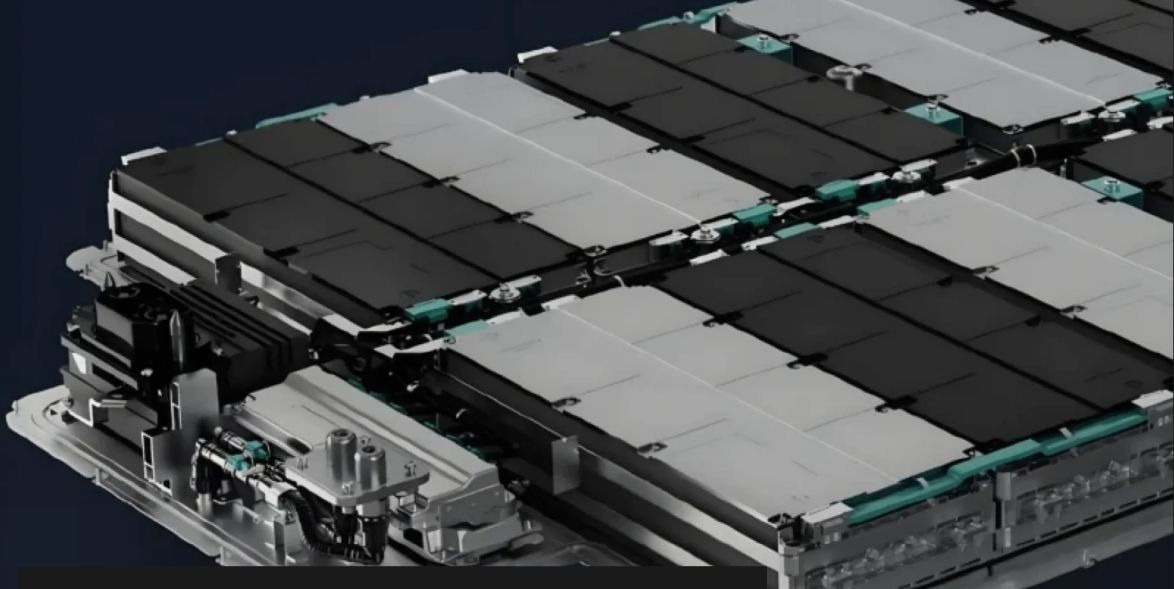

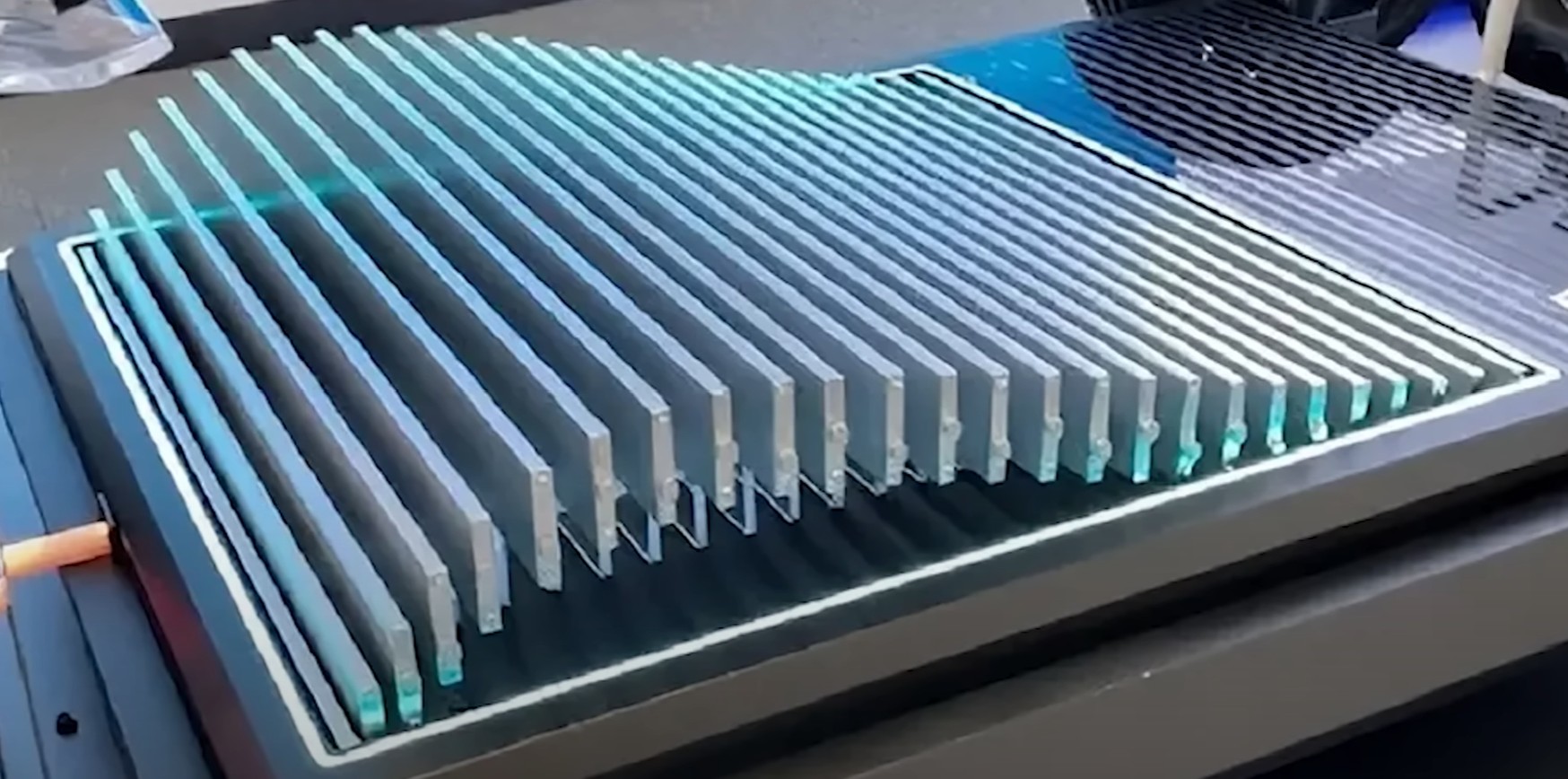

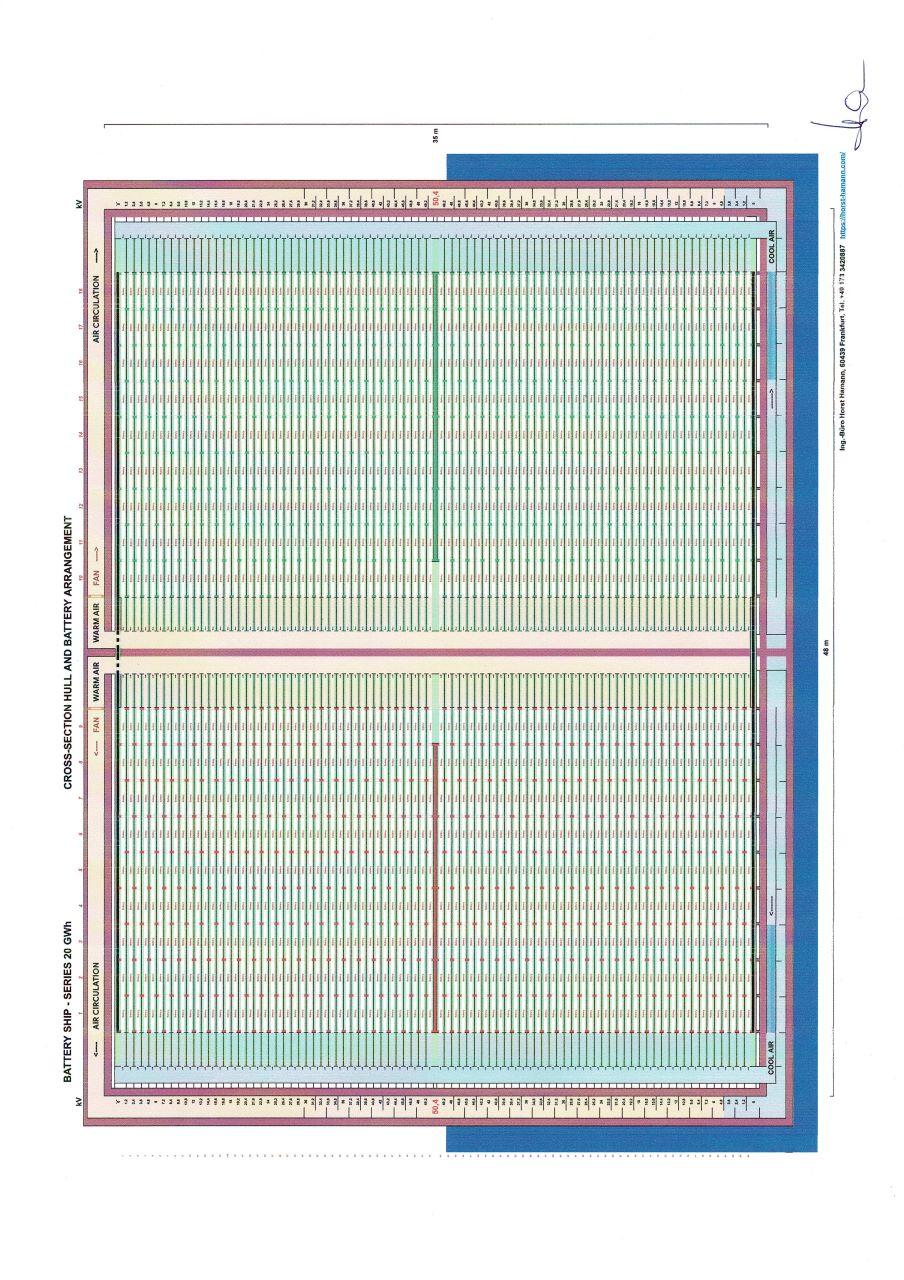

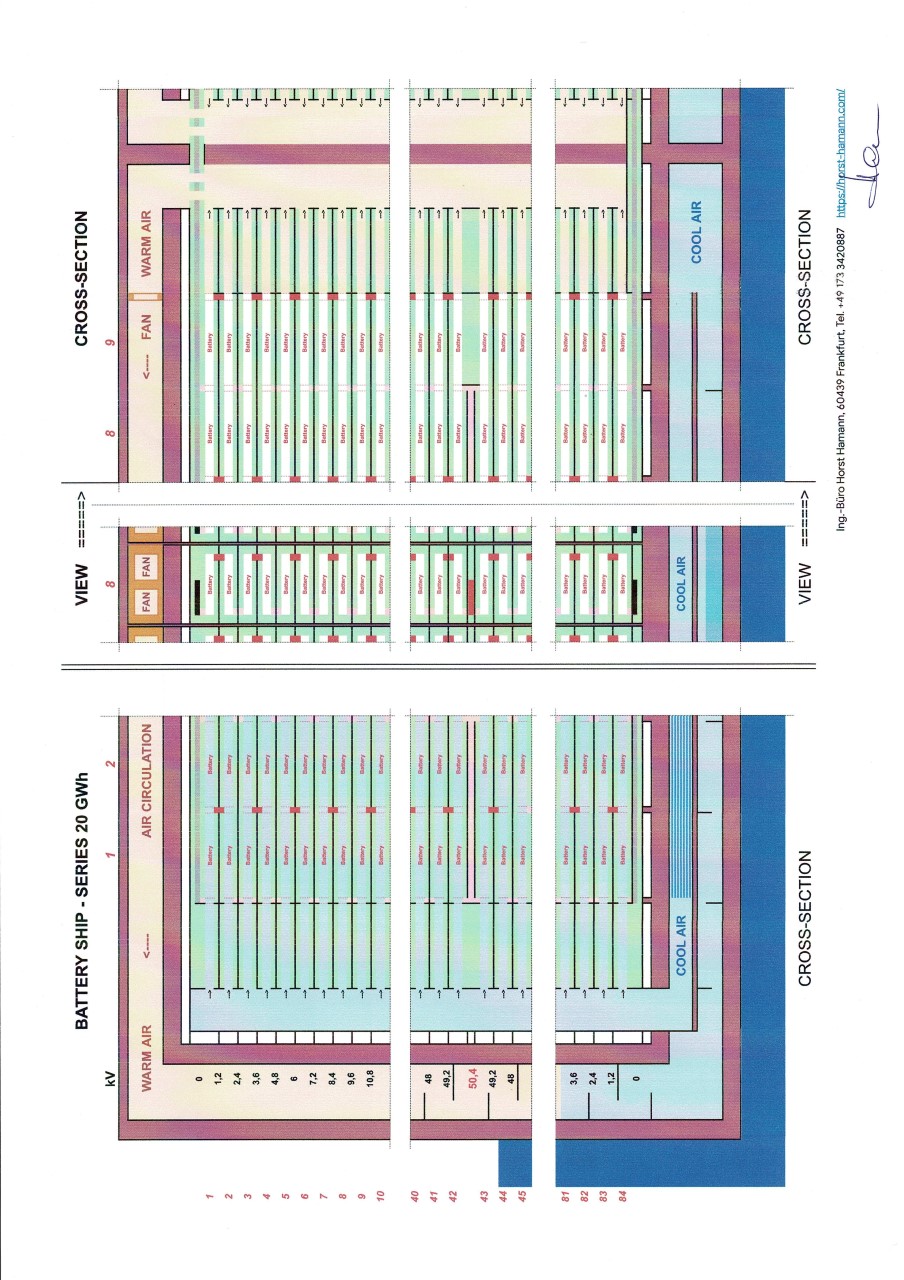

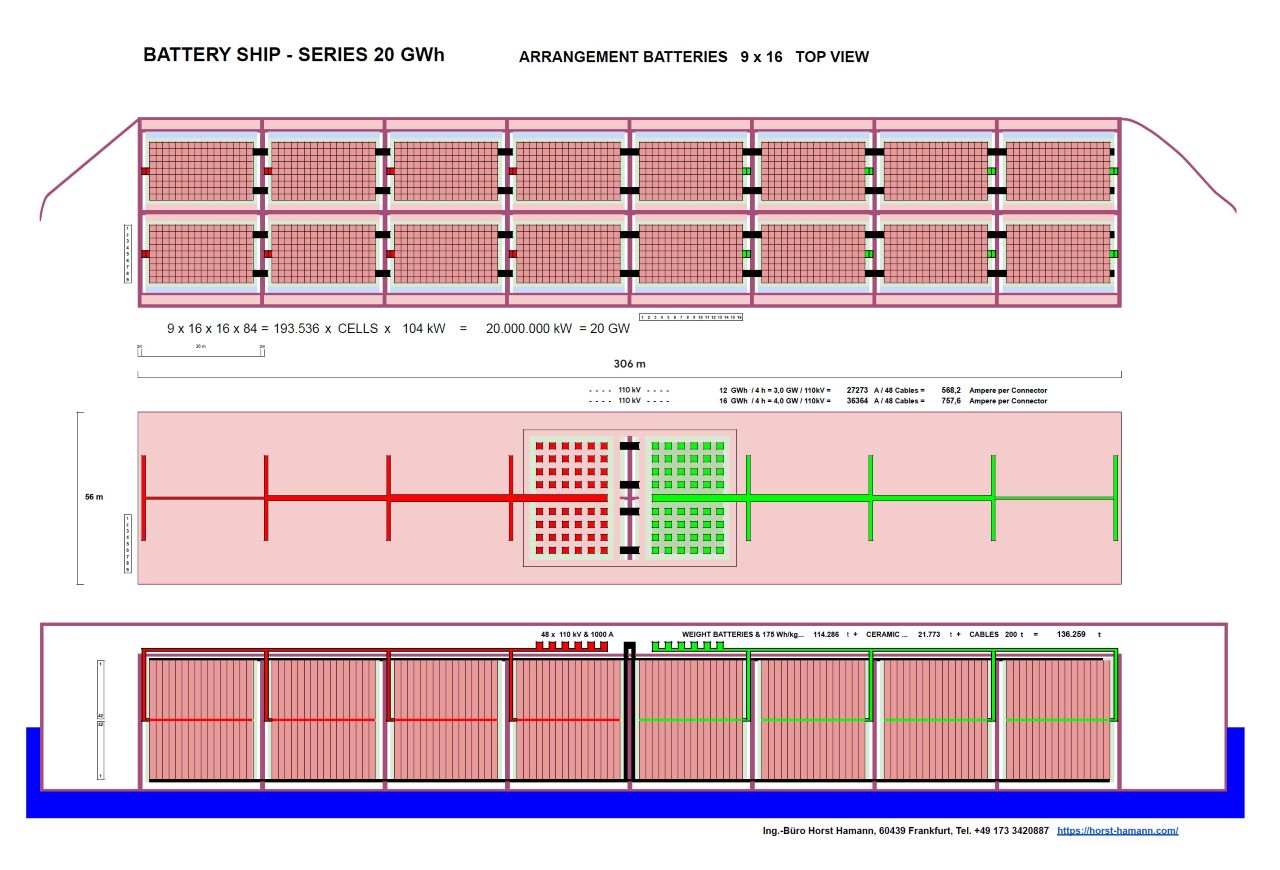

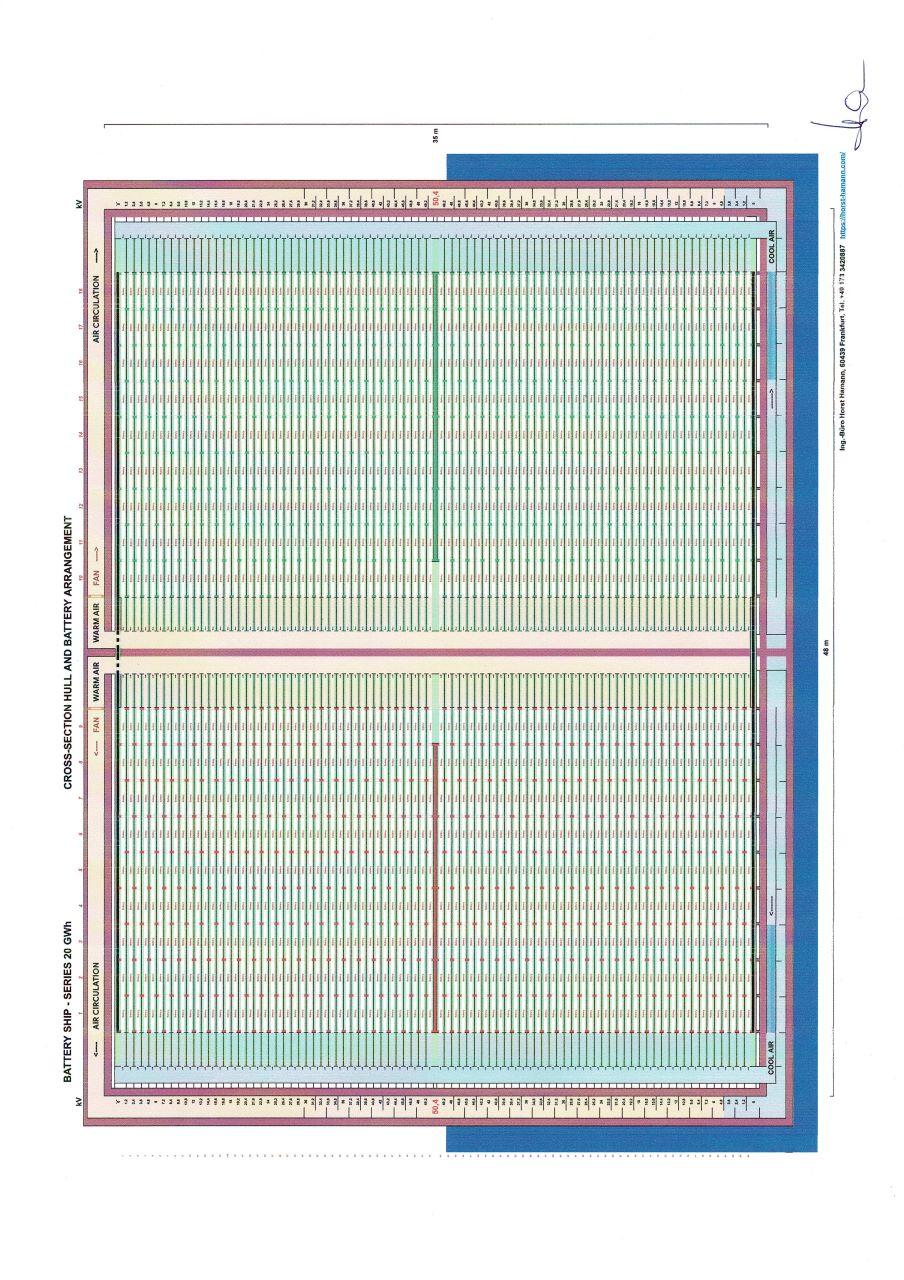

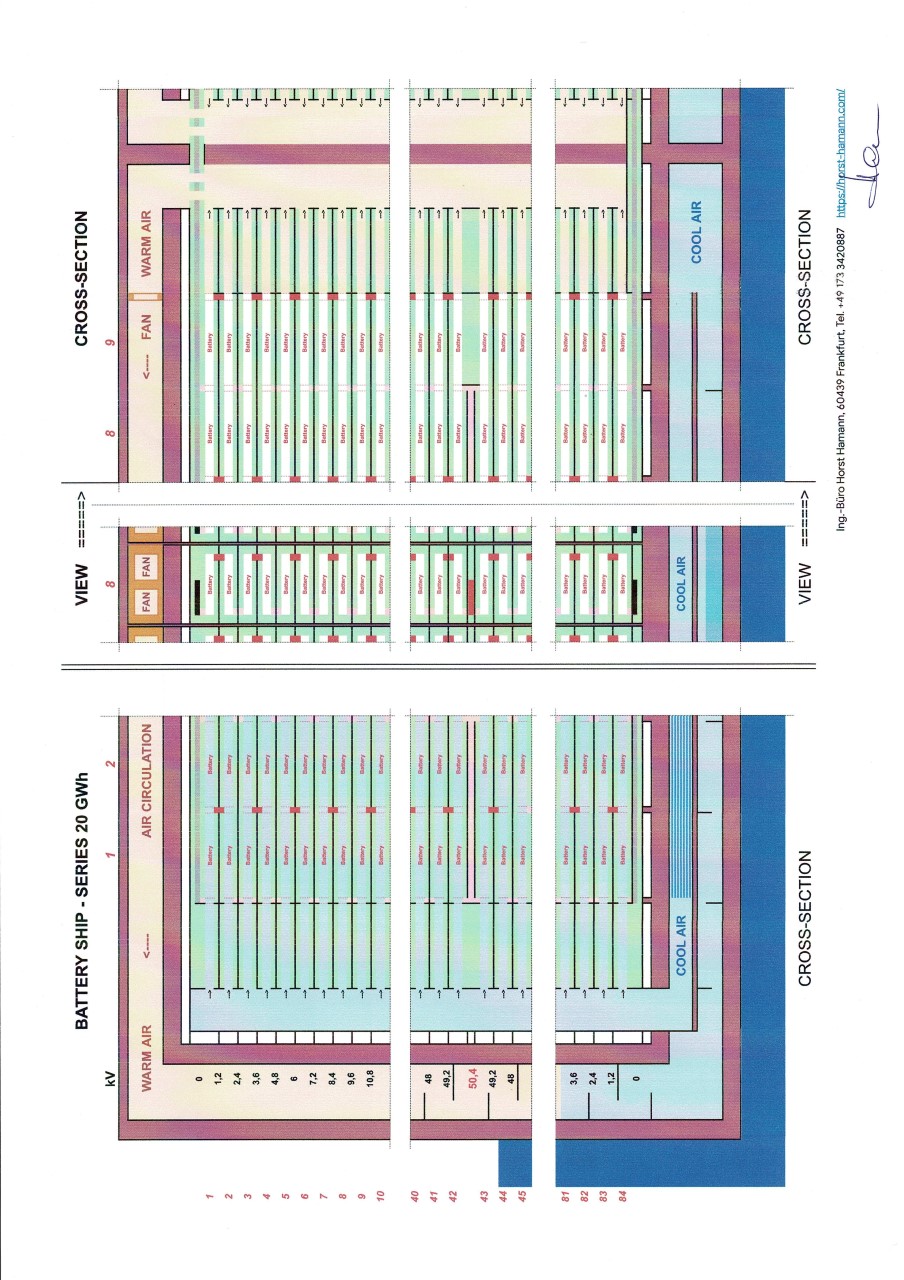

Typical: "View" onto the battery staples in a Battery Ship

---------------

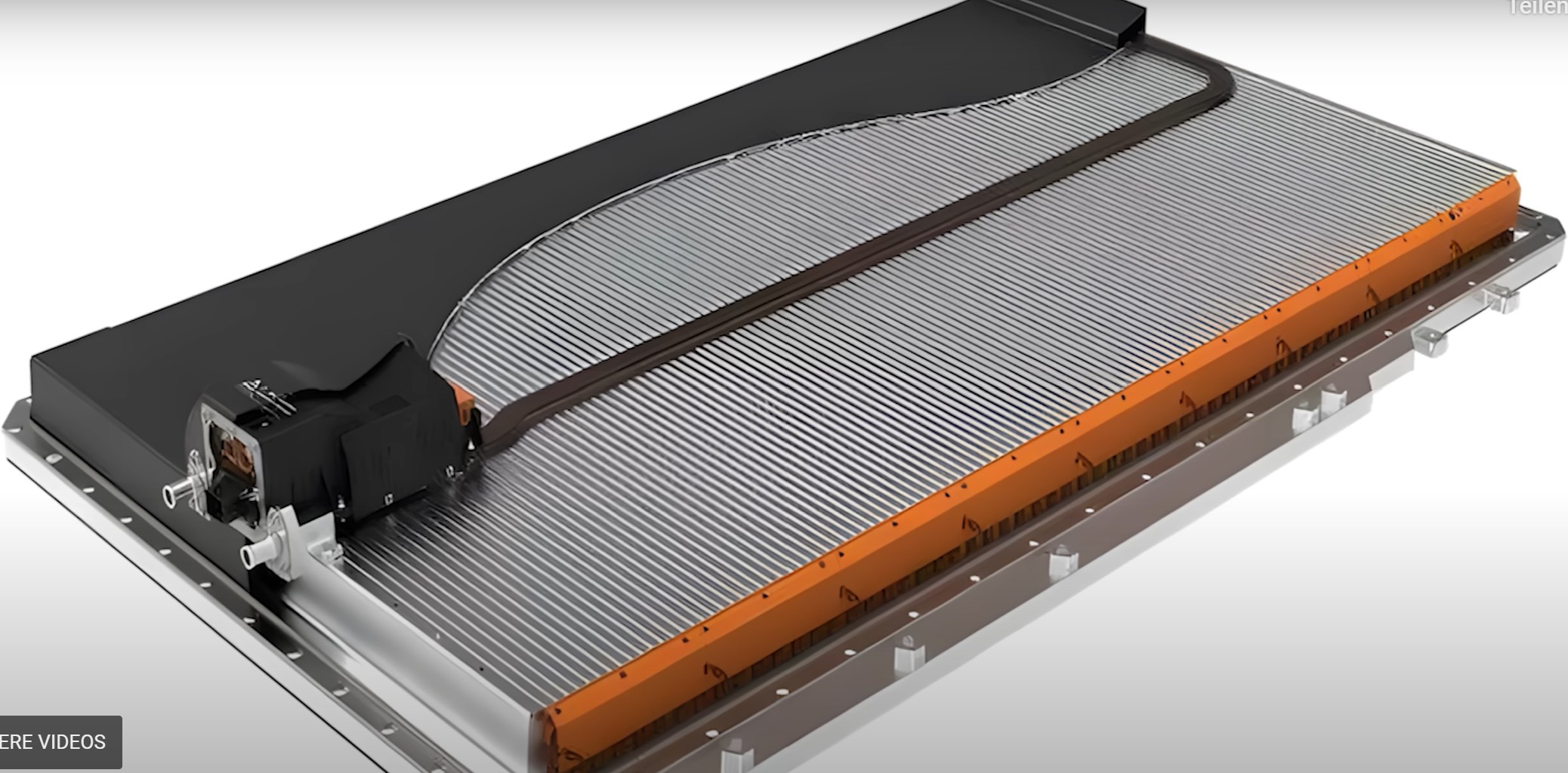

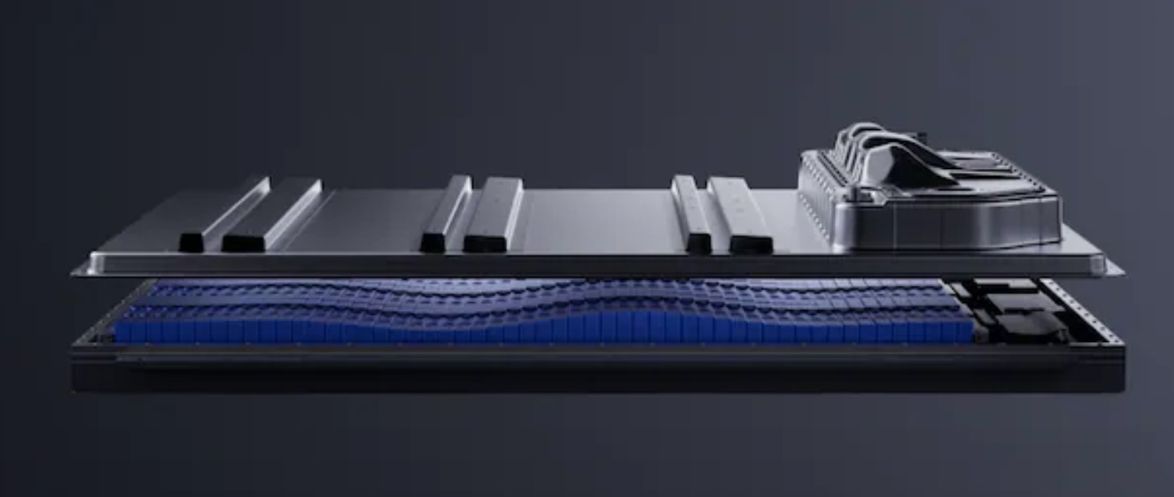

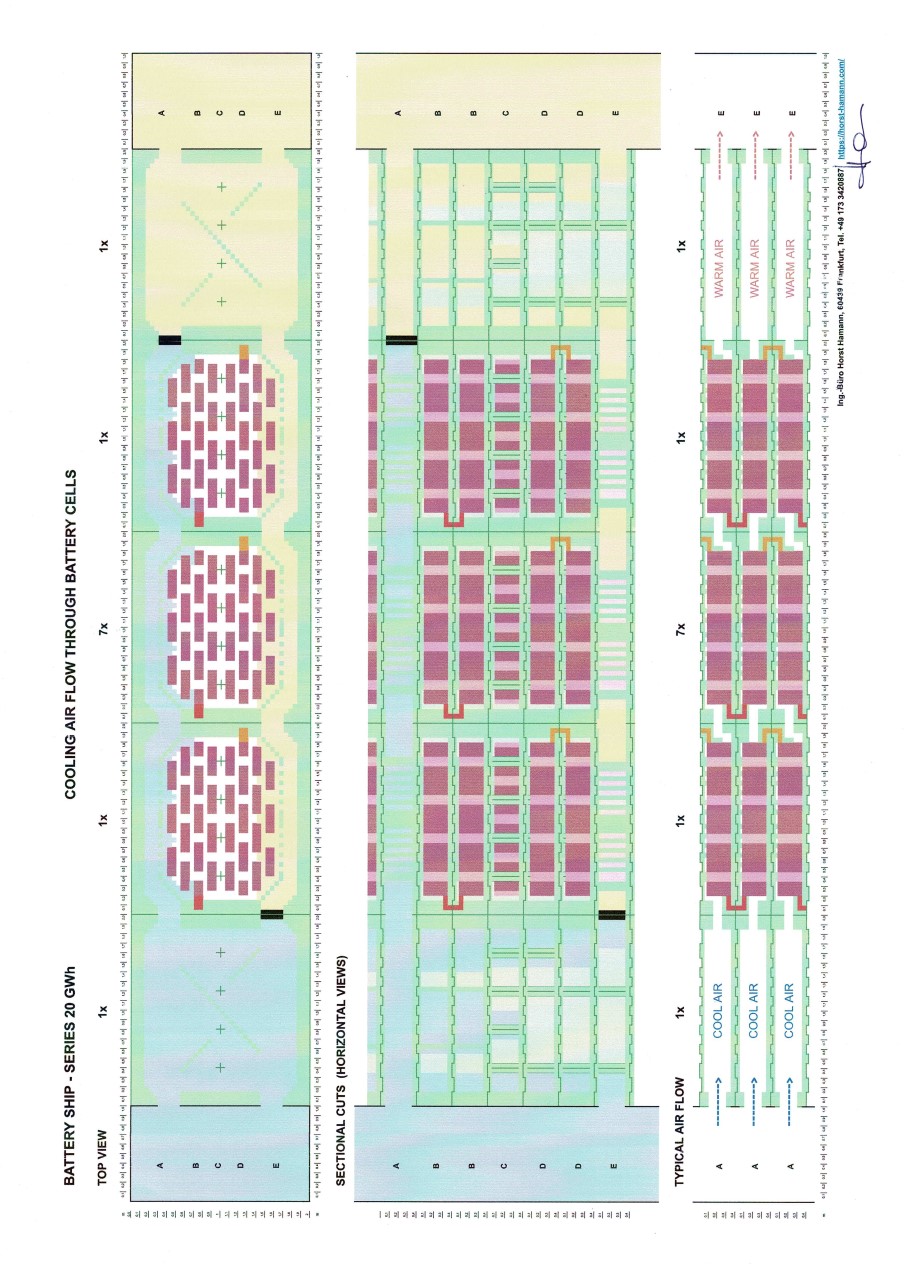

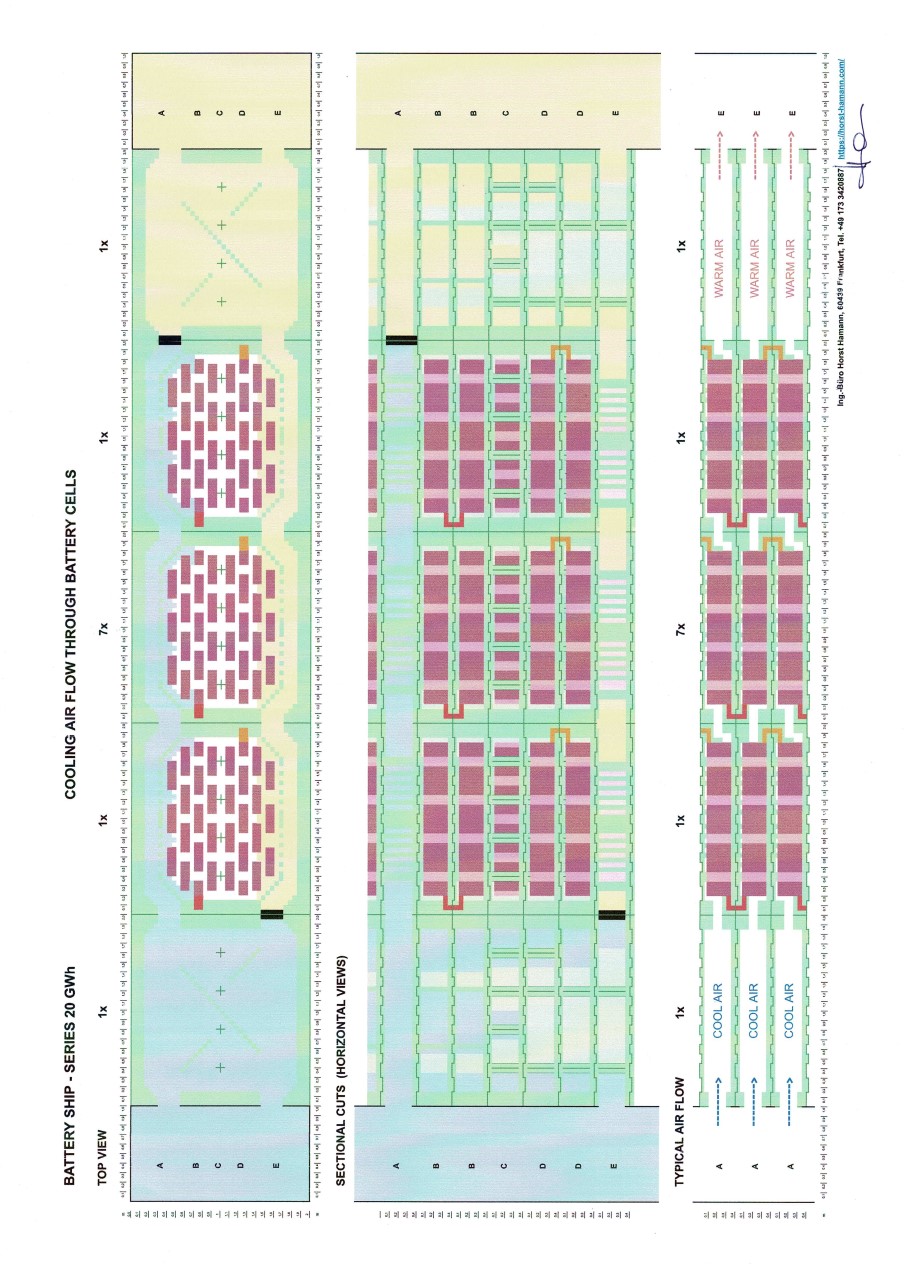

Typical: The proposed arrangement of cells and the cooling loop

---------------

Typical: The proposed arrangement of cells for equal cooling. Cooling controls and details are not shown in the picture below.

Temperature & cooling monitoring as well as additional fans are in other detail eng. drawings. In case of interest please ask.

Revised and updated designs are engineered and available.

---------------

Typical: The proposed methode of emergency cooling by injecting cold Nitrogen into the anyway overall cooling loop with Nitrogen

Revised and updated designs are engineered and available.

---------------

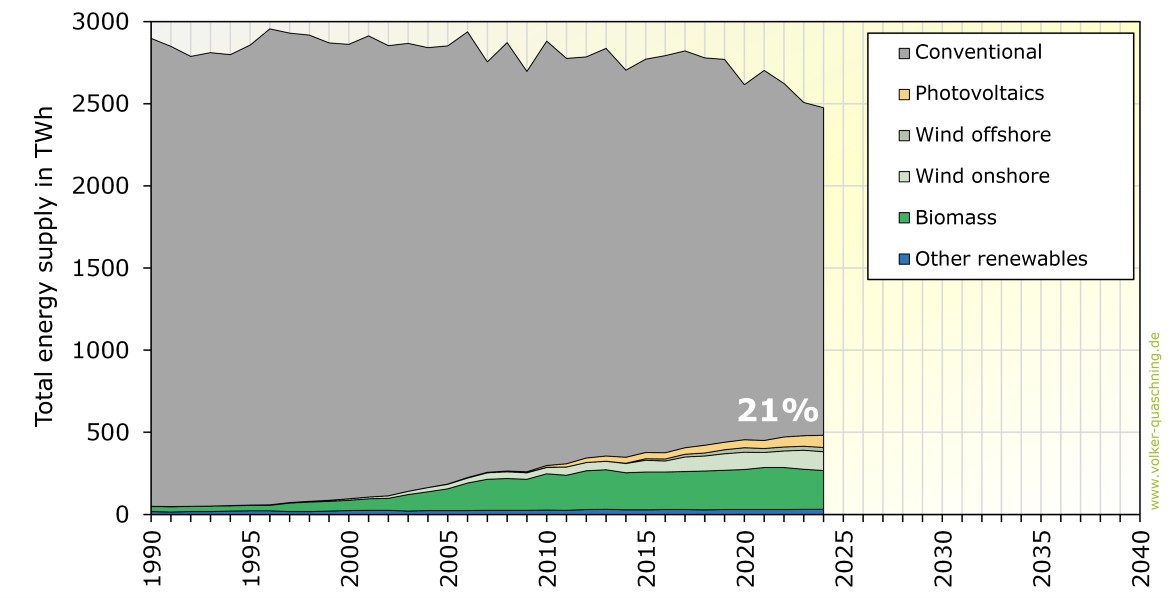

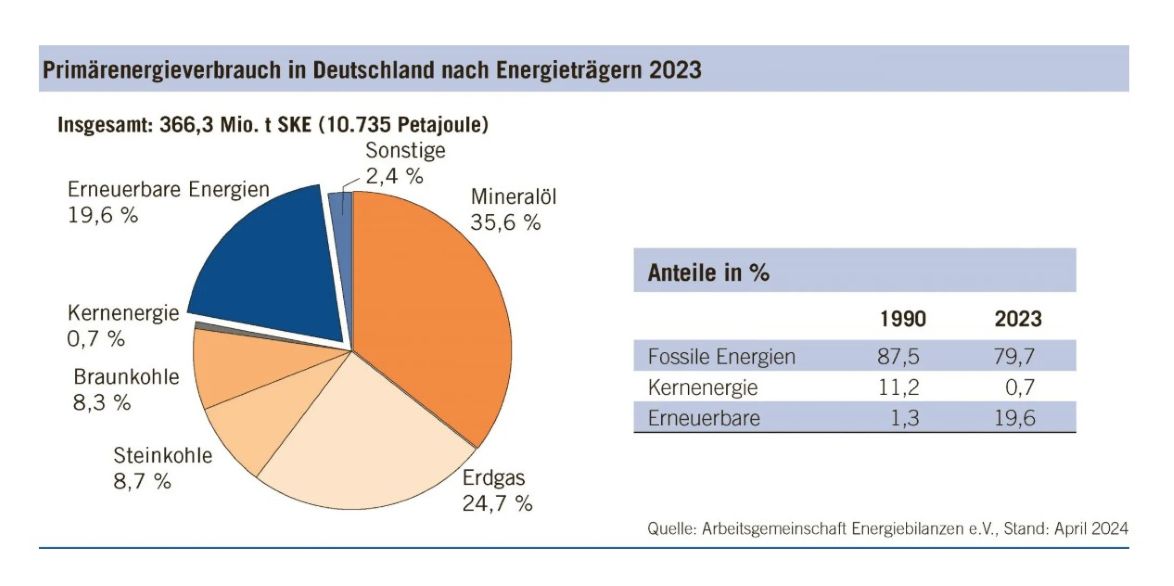

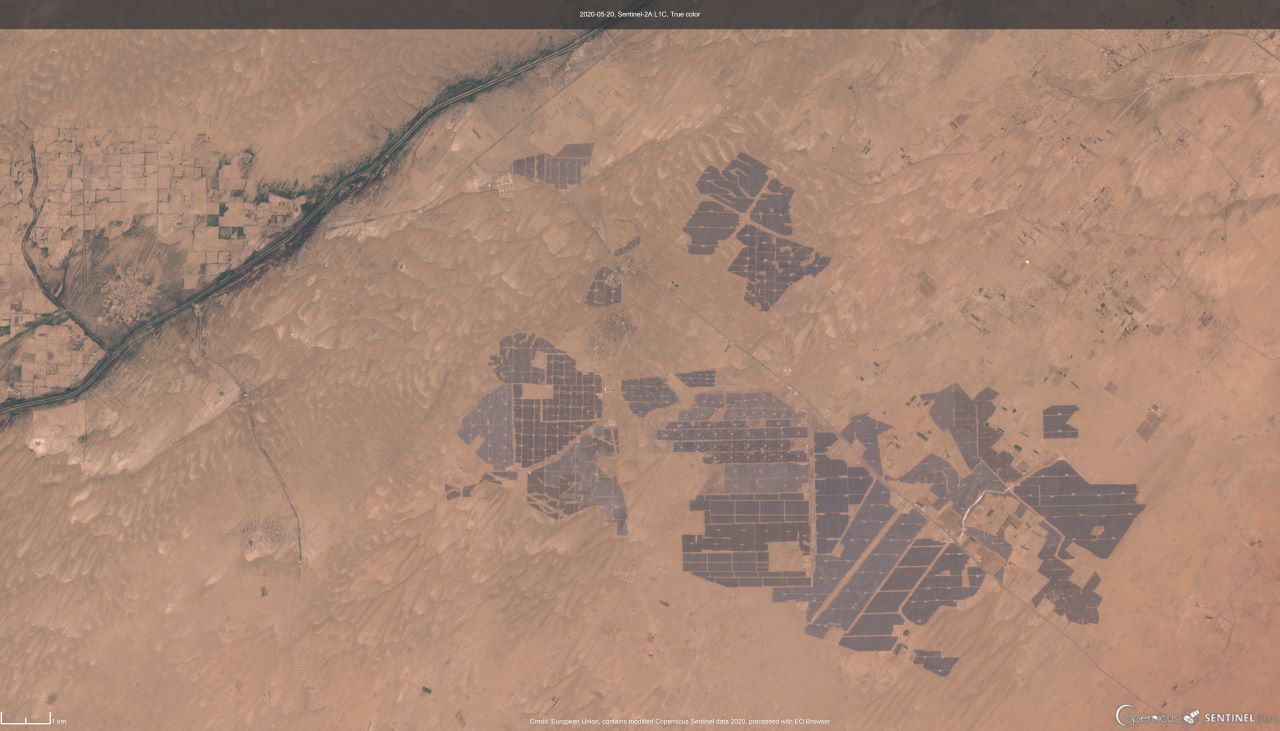

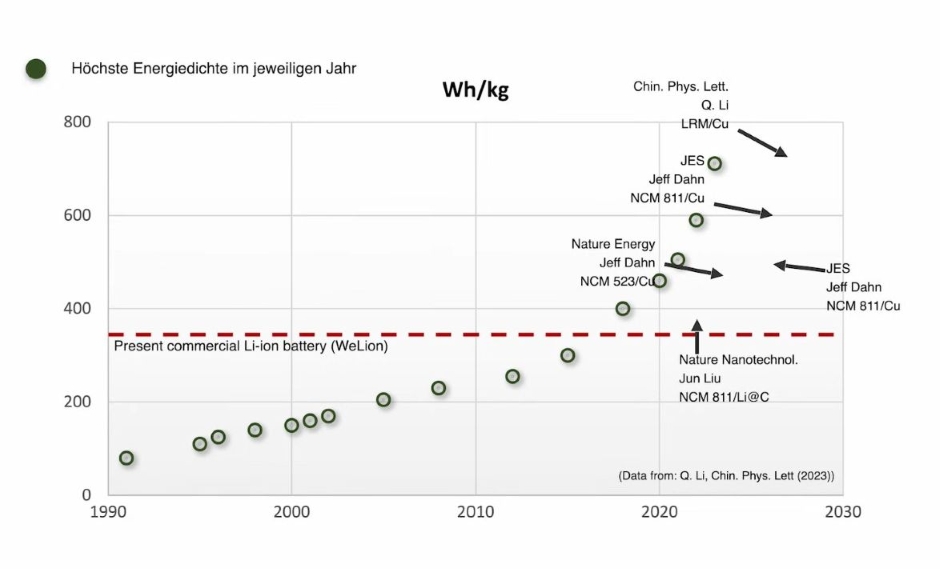

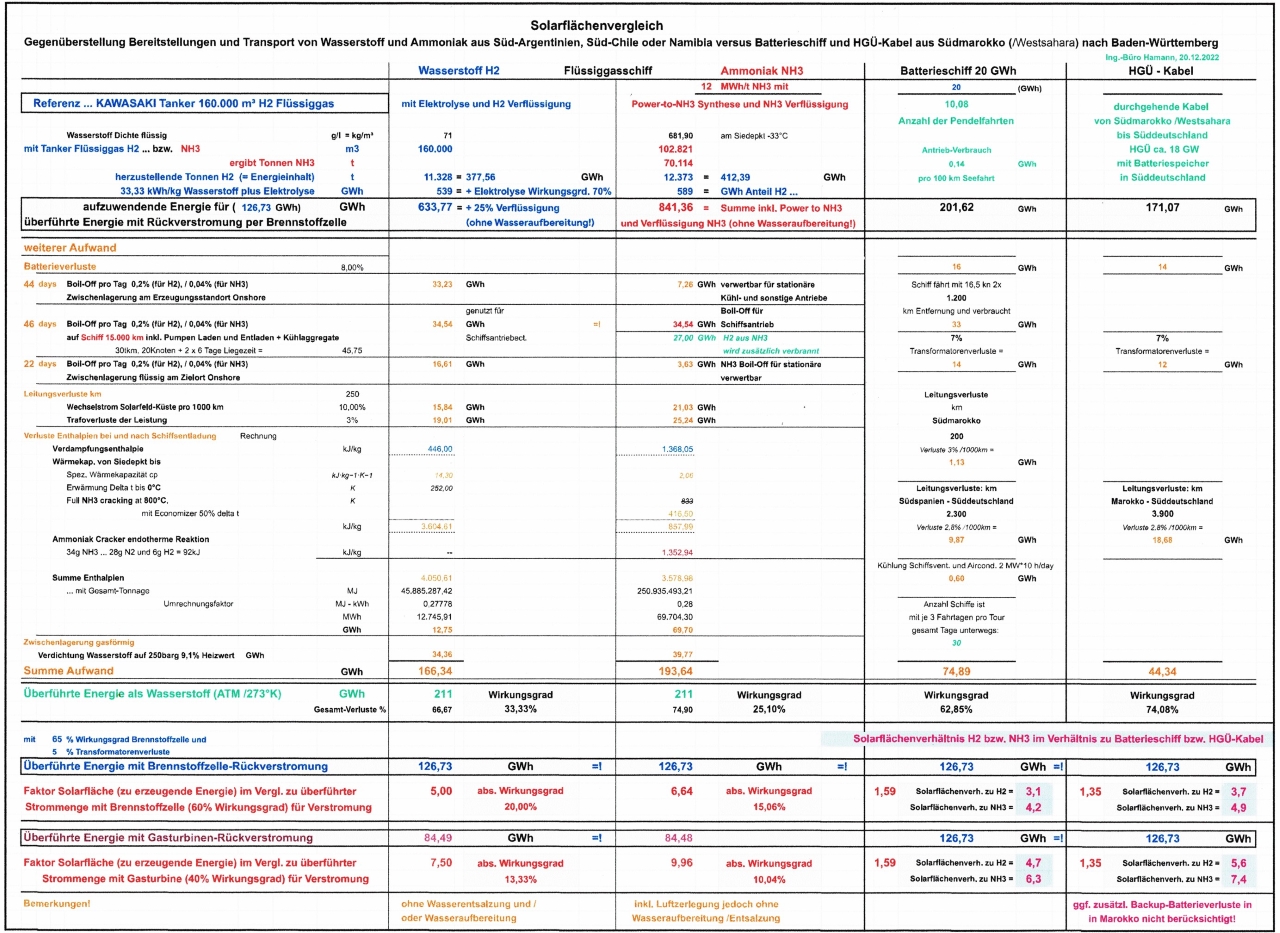

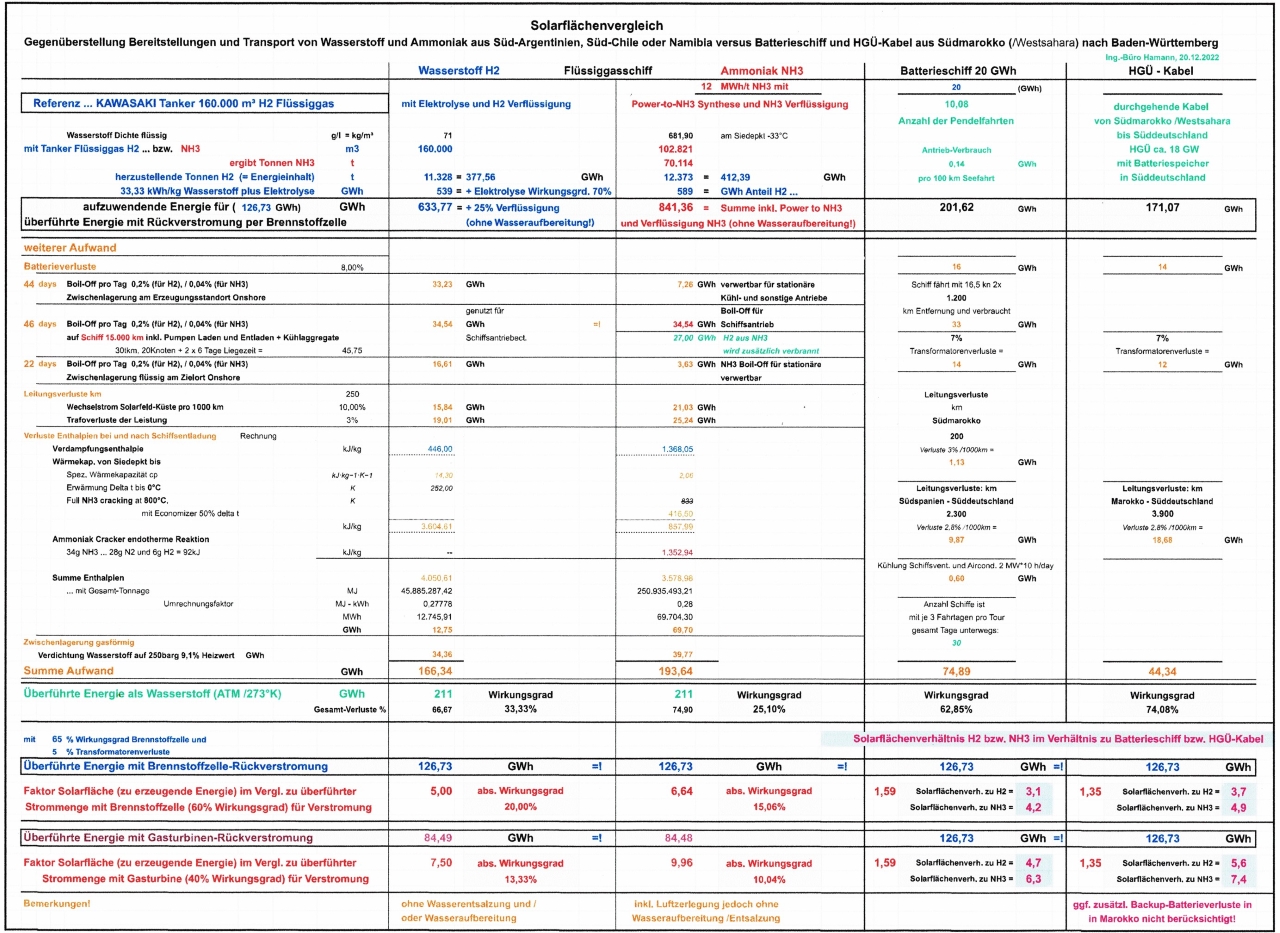

Solar Area Comparison: The following calculation shows significant differences in primary energy demand for the same electricity generation when using hydrogen, ammonia (each with fuel cell and gas turbine) and the direct use of battery ships or direct cabling. The calculation does not include a probably also required water desalination.

Required Solar Area (or equivalent wind power):

Ratio: Liquified Hydrogen Transport and power reconversion in Central Europe with gas turbines versus Battery Ships: ~ 4,7 / 1

Ratio: Liquified Ammonia Transport and power reconversion in Central Europe with gas turbines versus Battery Ships: ~ 6,3 / 1

The calculation below is in German - for more and detailed information please contact ...

---------------

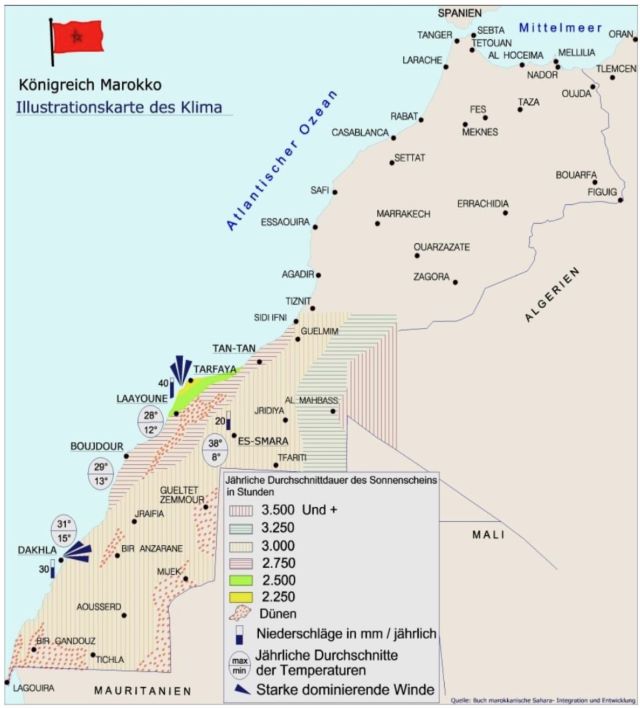

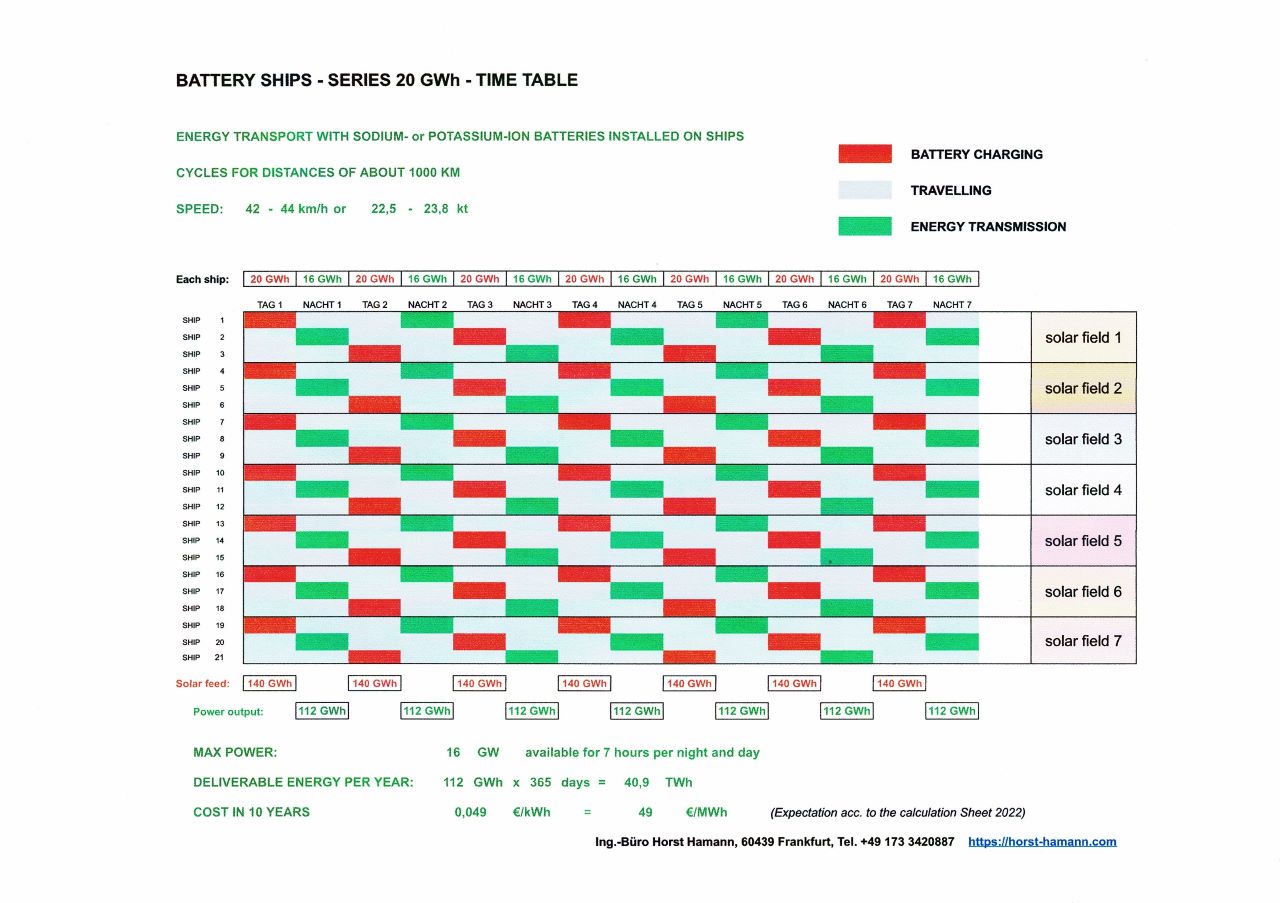

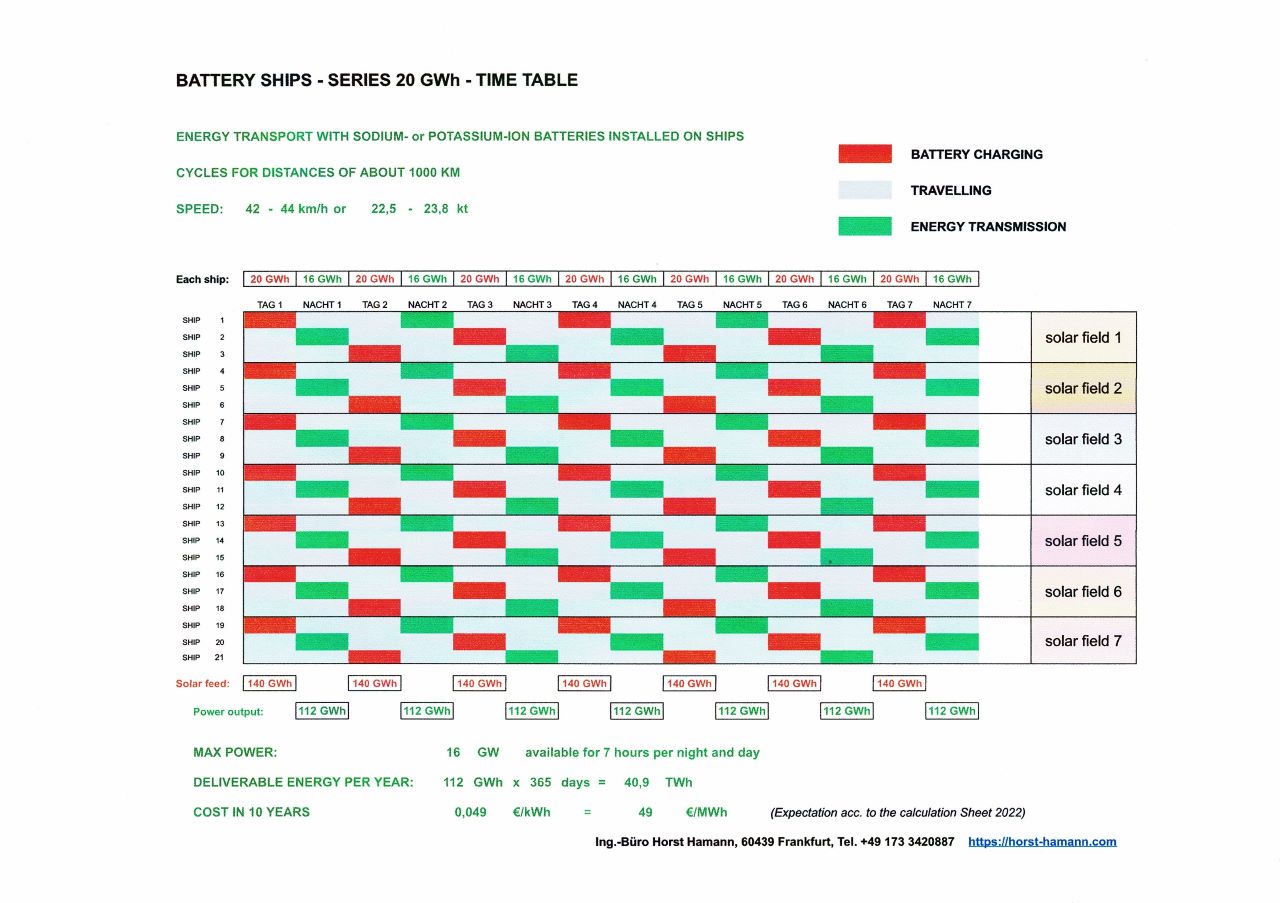

A proposed commuter schedule of ...below... 21 Ships for delivering 112 GWh solar energy each night at a level of 16 GW for stabilizing the grid in south Germany, Swiss and probably the Mulhouse area as well.

Of course, the battery ships can also be used for other electricity storage and on other energy transport routes.

---------------

High-voltage direct current (HVDC) technology

The director of the Fraunhofer Institute for Integrated Systems and Device Technology (FhG-IISB) and holder of the Chair of Power Electronics (LEE) at the Friedrich-Alexander University Erlangen-Nuremberg confirms the feasibility and implementability of the concept. No particular hurdles are to be expected in the area of power grid technology. For the cable route in Europe, the direct current could also be raised to a higher level.

---------------

A recently developed robot can reduce the time required to set up solar systems and the associated costs by up to 50 percent.

The robot primarily automates lifting work to precisely place solar panels. The robot uses artificial intelligence (AI), such as AI-supported computer vision, to independently set up the solar system as accurately as possible in real time. This robot, called Maximo, has already proven that this works when it built the Oak Ridge Solar Farm in the US state of Louisiana.

---------------

Large solar panels provide plenty of shade for the local soil, which can have a positive impact on the ecosystem.

The impact on local microclimates, i.e., the climatic conditions near the ground and thus the physical and chemical properties of the soil, which promote the diversity of plant and microbial communities, is positive.

The photovoltaic modules absorb direct sunlight, which leads to reduced soil moisture evaporation.

Modules block long-wave radiation from the ground into the atmosphere, which affects the radiation balance of the Earth's atmosphere interface.

At the same time, the necessary cleaning of the modules increases soil moisture in the area and thus also the air humidity below the solar panels.

=========================

Some Engineering References /History

Clariant, Sunliquid Project, Romania

Process and technology manager of the technology group in Frankfurt, early detection of expected process errors and development of proposed solutions (unfortunately, Clariant management refused to listen to me, so the project became a very expensive and ultimately shut-down plant due to process errors).

---------------

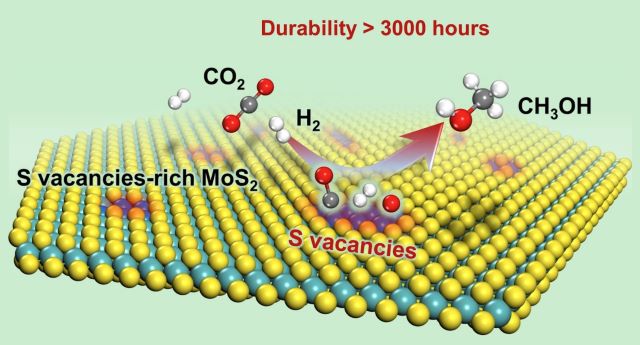

RZR Herten, Germany, Waste Power Plant

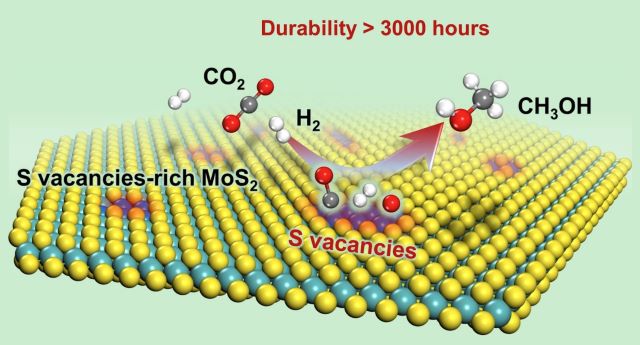

Process, study, plausibility and recommendation analysis for the intended introduction of methanol synthesis from green hydrogen and CO2 from waste incineration as a replacement for the fuel used in garbage trucks.

---------------

Yara Norway, Bamboo project, Revamp, Capacity Expansion

Engineering of a Process Air Conditioning Unit, 2,5 MW heat removal added to an existing air flow; concept, technical clarification, engineering, P&IDs, functional description ...

also inquiries and POs for all pumps of the project.

---------------

ThyssenKrupp Industrial Solutions (Uhde) Dortmund, CHS Fertilizer Plant (North Dakota)

Preparation of Technical Data Sheets for Blowers and Oil Systems.

---------------

Coker Yield Improvement Project (BP)

Select Phase for Wet Gas Compressor and Decoking Jet Pump.

---------------

Onshore Wind Farm Northern Germany

Wind to Liquids project, Initiator of a conceptual study (2011) and project design for the production of renewable synthetic fuels using overproduced current by electrolysis, Sabatier process and Fisher Tropsch synthesis, incl. accessories (connections to an existing biogas plant and a refinery, carbon capture recommendation, CO2 transport).

---------------

OMV Petrom, Romania

Slug Catcher for a gas pipeline, design analysis (flow, piping impulses, fire cases etc.). Process recommendations for process water treatment plants.

---------------

Chemical Plants (Maasvlakte, Botlek Rotterdam) LyondellBasell, Netherlands

Process related innovative compressor design concepts for efficiency & process upgrades with heat integration. Analysis of caustic waste water treatment concepts, heat balances. Guidelines for environmental upgrades. (2011)

---------------

Vattenfall Europe, Jänschwalde /Alstom Carbon Capture - Plant Project

Plant P&IDs (design), design of a Reclaimer package unit etc. (2010)

---------------

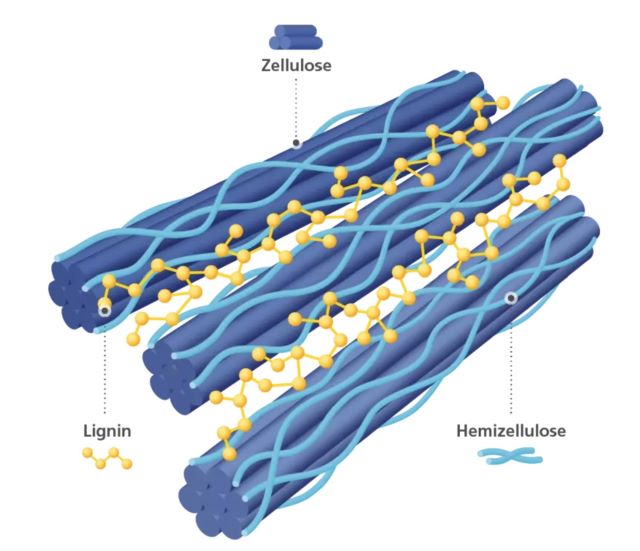

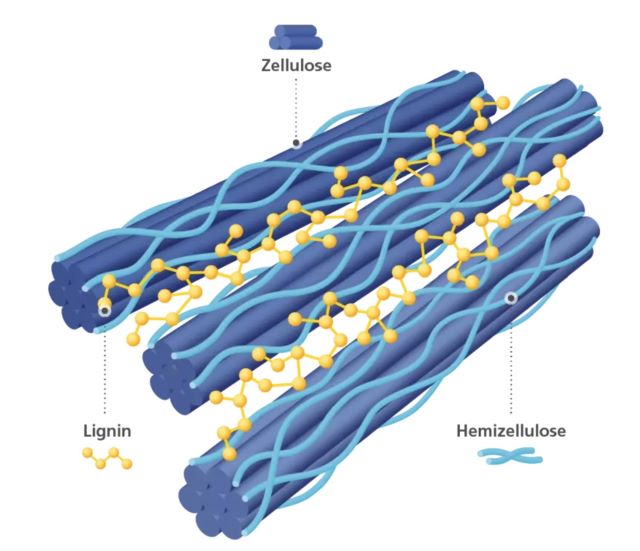

Lignin Project

Study on the use of lignin as a structural material to remove CO2 from the atmosphere and bind it in the long term.

(2009)

---------------

Oil & Gas Companies in Libya and Algeria /MAN Ferrostaal

Gas Turbine-Generator power plant (MAN Turbo) for Harouge Oil Operations in En Naga incl. PFD, gas turbine selection for the desert environment, gas processing (Soave-Redlich-Kwong), fuel gas compressor, plant arrangement.

Corrosion analysis & material guidance for column repairs.

Detail engineering of high pressure spheres including material analysis after cladding difficulties (Super Duplex), examinations, hydrostatic tests, FATs.

Detail engineering (inquiry, bid comparison, drawing checks) of heat exchangers, testing.

Leading the repair of a metering unit at site in Libya. Leading commissioning of a flare.

Quotation for a GOSP revamp and upgrade with new Turbos and new Reciprocating Compressors (Dresser), explaining in detail the concepts to the client in Algeria.

Claim management.

---------------

OMV-Germany META Project Burghausen - revamp and new plant /ABB

Revamp of an Ethylene plant and engineering (mech.) of a new Olefin Conversion plant.

Detail engineering /inquiry, bid comparison, technical clarification meetings, testing, documentation, delivery.

Installation, commissioning and start up of pumps, compressors and steam turbines (Siemens).

Analysis of seal and possible pump failures and early recommendations for changes. Responsible for the settings of the seal systems. Explanation of the functionality to the operators.

Analysis of claim accusations.

---------------

GTL - Syntroleum Sweetwater Project

Fischer-Tropsch, Gas to Liquid /Australia

Turbo compressors with steam turbines (up to 60MW), Pumps, Generator, Screw compressor, Air cooler, cooling tower, fire fighting, bio treatment (all ready for purchase).

---------------

Ethylene plant - revamp BIPC /Iran (Bandar Imam) /CB&I

New turbo compressors with steam turbines (MHI /cracked gas, ethylene, propylene compressors) with dry gas seals, including revision of existing P&IDs.

New condensers, new expander-compressors with magnetic bearings (Cryostar), agitator, new boiler feed water pumps, new cooling water Inquiries, technical clarifications, bid comparison, detail engineering, e.g. design pattern for the human machine interface, performance testing, hydrostatic tests of the condensers, FATs of the control panels.

Presenting the machines to the client at manufacturers, FATs.

---------------

Ethylene plant Tiszai Vegyi /Hungary /Linde

Turbo compressors with condensing steam turbines (MAN-Turbo), Inquiries, technical clarifications, bid comparison, detail engineering.

---------------

Project for BASF /China /ABB Lummus

Instrument air compressor, kneaders, thermo reactor Inquiries, technical clarifications, bid comparison, purchase.

---------------

Projects for National Oil Distribution Company, Qatar / Buthyl Lithium, Taiwan / Yangtse River Acetyls Company, Sichuan (BP) / Leuna 2000 Refinery (Lurgi, Metallgesellschaft), Germany ... an more

---------------

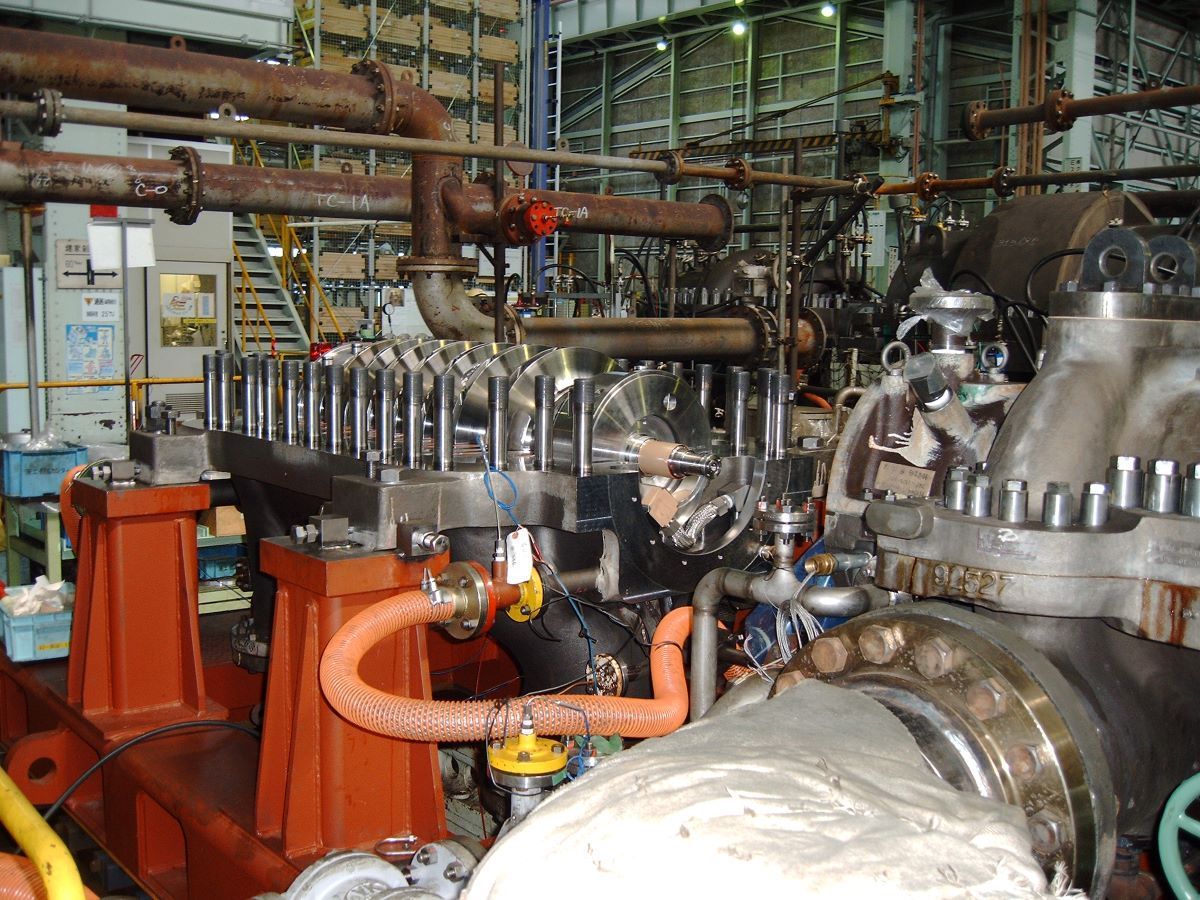

Test bench of a compressor

One of the more smaller items

Revamp of a column

One of the missions was completed

Construction site experiences are always something special when they confirm your own designs, calculations and specifications without errors. Thanks to our precise documents, quality control and approval management, we have always had joy, success and recognition on construction sites.

=============================

Current Office Location

(Remote Storage)

Dipl.-Ing. (TU) Horst Hamann, 60439 Frankfurt, Thomas-Mann-Str. 55

Phone: +49 173 3420887

Hamann studied Engineering and Biology.

The Kiosk in Google's map is not the office, the office is just close by.

(Frankfurt History: This Kiosk was built in the 1960s and is one of the so-called Frankfurt "Wasserhäuschen .... water houses" which are a traditional part of the Frankfurt cityscape and are still more than just kiosks for many locals today. These drinking halls were built in the second half of the 19th century. At that time, drinking unboiled tap water was a hygiene concern, but it was the first time that mineral water could be bottled while maintaining the gas pressure. The city-approved water houses were intended to help workers drink more water by selling these bottles and not - as was so often the case - beer and liquor. It was also known colloquially as "Bitzelwasser". Since the water houses were not tied to the official shop closing times, there were at times up to 800 drinking halls in the city. Today "our Wasserhäuschen" is run by an Indian mainly selling beer.)

-----------------------------------

Videos

Sun, wind, tides, geothermal energy – they never run dry.